Diesel Exhaust Fluid Contamination: Forms, Causes, and Consequences

Overview

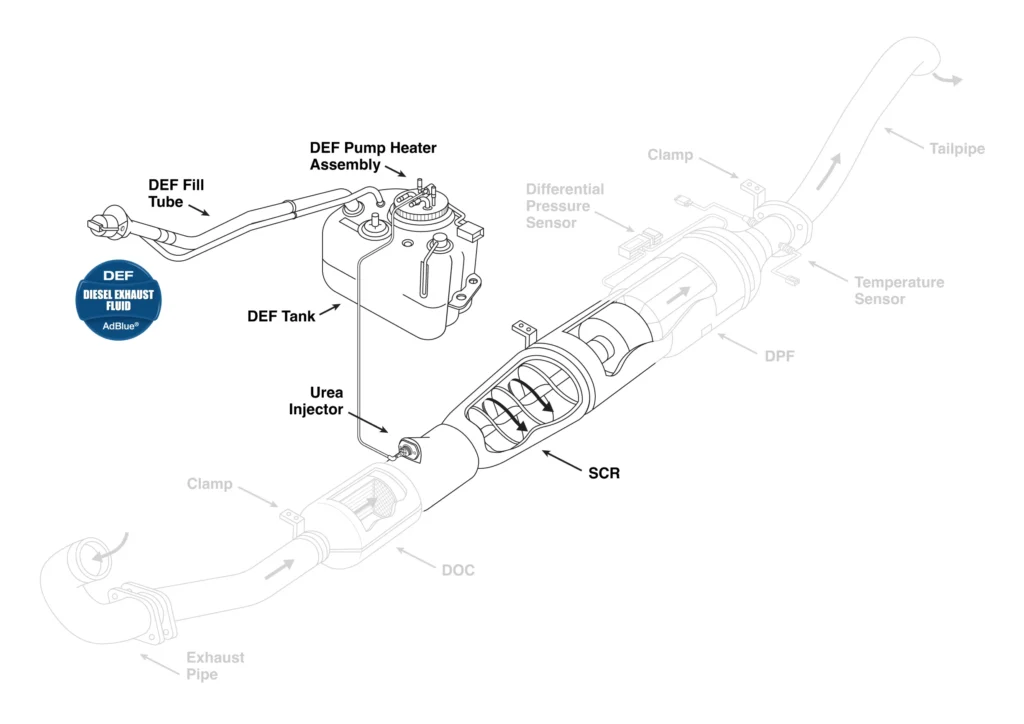

Diesel Exhaust Fluid (DEF), a urea-water solution critical for reducing nitrogen oxide (NOx) emissions in modern diesel engines, is highly susceptible to contamination. Contamination can manifest through cross-mixing with incompatible fluids, chemical degradation, or particulate introduction, leading to engine malfunctions, selective catalytic reduction (SCR) system failures, and costly repairs. This post examines the forms of DEF contamination, their root causes, and consequences, while contextualizing normal operational phenomena — such as additive-induced foaming — against genuine risks.

Forms of DEF Contamination

1. Cross-Contamination with Other Fluids

DEF is most commonly contaminated through accidental mixing with fuels, additives, or incompatible chemicals. In aviation, DEF has been confused with Fuel System Icing Inhibitor (FSII), a jet fuel additive, leading to crystalline deposits that clog filters and fuel lines. Similarly, misdispensing DEF into diesel fuel tanks (more common among new diesel owners) causes chemical reactions that corrode metals (e.g., aluminum, copper) and degrade fuel system components.

2. Chemical Degradation and Crystallization

DEF decomposes when exposed to temperatures above 86°F, releasing ammonia and forming solid urea crystals. Crystallization clogs SCR injectors, sensors, and decomposition chambers, impairing NOx reduction and triggering engine derates. Contamination from metals (e.g., zinc, nickel) or organic matter further accelerates this process, reducing DEF’s shelf life and efficacy.

3. Particulate Contamination

Even minor impurities — dust, dirt, or residual chemicals in storage containers — can render DEF non-compliant with ISO 22241 standards. A single penny contaminates 10,000 gallons of DEF, while a half-tablespoon of dirt ruins hundreds of gallons. Particulates obstruct filters and injectors, leading to SCR system failures.

Causes of DEF Contamination

1. Human Error in Handling

Misidentification of fluids: DEF’s visual similarity to FSII and water has led to aviation incidents where DEF was injected into jet fuel systems.

Improper storage: Co-locating DEF with fuels or chemicals increases spill risks. DEF stored in non-approved containers (e.g., carbon steel) corrodes, leaching metals into the fluid.

2. Environmental Exposure

Temperature fluctuations: Prolonged heat (>86°F) decomposes urea, while freezing (<12°F) causes phase separation and crystallization.

UV exposure: Direct sunlight degrades DEF, reducing its NOx-reducing capacity.

3. Inadequate Quality Control

Non-API-certified DEF often contains impurities like aldehydes or biuret, which damage SCR catalysts. Field tests using refractometers are critical to verify urea concentration (32.5%) and purity.

Consequences of Contamination

1. Engine and SCR System Damage

Crystallization: Urea deposits block DEF injectors, causing incomplete NOx reduction and triggering fault codes (e.g., P20EE, P207F).

Corrosion: DEF’s alkalinity (pH 7.0–9.5) corrodes aluminum, brass, and copper in fuel systems, leading to leaks and electrical failures.

2. Operational Failures

Limp mode: Contamination-induced SCR faults force engines into reduced power states to limit emissions.

Fuel system replacement: DEF in diesel fuel necessitates full system flushing and component replacements, costing upwards of $3,000 for SCR units.

3. Regulatory and Financial Impacts

Non-compliance with emissions standards risks fines, while contaminated DEF voids warranties. Aviation incidents, such as the 2017 Omaha fuel contamination, highlight catastrophic safety risks.

Normal vs. Abnormal Phenomena in DEF Management

1. Additive-Induced Foaming

Foaming during DEF refills is normal when using additives like Rislone Diesel DEF Treatment, which contains surfactants to dissolve crystals. This transient foaming does not indicate contamination and resolves upon settling. In contrast, persistent foam with cloudiness or odor signals impurities.

2. Expected Crystallization in Cold Climates

DEF naturally freezes at 12°F but thaws without degradation. SCR systems include heaters to mitigate this. Abnormal crystallization—resulting from urea decomposition or contamination—requires intervention.

3. Routine Maintenance and Additives

Prophylactic additives like Rislone DEF Crystal Clean dissolve deposits, while Rislone DEF Treatment prevents recurrence. These products are compatible with all DEF fluids and do not void warranties when used as directed.

Mitigation Strategies

Storage and Handling Protocols

Store DEF in HDPE containers at 12–86°F, away from UV light and contaminants.

Label DEF and FSII containers clearly, using dedicated transfer equipment.

Quality Assurance

Use API-certified DEF and verify purity with refractometers.

Implement electronic conductivity tests to detect DEF-FSII mixing.

Additive Utilization

Rislone DEF Treatment: Prevents crystallization at 2–8 oz per 10 gallons.

Rislone DEF Crystal Clean: Clears existing deposits and resets SCR fault codes.

Conclusion

DEF contamination poses significant operational, financial, and safety risks, but proactive management mitigates these threats. While additives like Rislone’s introduce benign foaming, they play a critical role in maintaining SCR health. Industry-wide adherence to ISO 22241 standards, coupled with advanced additives, ensures DEF’s efficacy in meeting emissions targets without compromising engine performance.

This post synthesizes findings from industry reports, technical guidelines, and product data. For further details on DEF handling, refer to the FAA-NBAA Working Group Report (2019)(1), and API Standard 1509(2).