Expert Overview: What Causes Engine Compression Loss Anyway?

Most of the time, engine maintenance doesn’t require you to take your vehicle to the shop for an expensive repair. And doing it yourself can much more rewarding anyway. If you’re like us at Rislone, you want your engine to perform at its peak levels, whether your car is a hard-working truck, performance car, or average family sedan.

Your engine keeps your life moving, and you expect it to remain reliable and efficient. But when problems start to occur, the best thing you can do is educate yourself before taking it to a dealership or mechanic.

Engine compression loss can be the result of many faulty components, so we’re going to give you a rundown to show you each possible problem and how you can perform easy and effective repairs.

Engine Compression Explained

Whether you’re a car enthusiast or like to learn as you go, it’s essential to gain insight into how various components of an engine work. Once you have a basic foundation, it will be easier for you to find problems and fix them on your own.

Your vehicle has an internal combustion engine (sometimes noted as ICE) that relies on compression to transfer energy. Compression occurs in the internal combustion cylinders as the fuel injectors push air and fuel into the combustion chamber. The mixture ignites, and the expansion of the burning gases in the cylinders drives the piston, transferring the energy from combustion into mechanical energy that moves the vehicle.

Because the cylinder compresses the air and fuel before they ignite, compression is a vital process that allows a vehicle to operate. Compression loss is a result of a leak in one or more of the cylinders caused by normal engine wear and tear.

If you experience compression loss in one cylinder of the engine, it can cause misfiring and poor vehicle performance. A decrease in power output is a sign of worn-out internal parts. Sometimes, an engine misfire code may indicate compression loss, but first, check the ignition and fuel for problems. If both are fine, it’ll be time to investigate the cylinders for proper compression.

In the case that no compression exists at all, it means a more severe mechanical problem occurred, causing your engine not even to start. When the cylinder doesn’t create enough compression, then there isn’t enough force to move the piston and crankshaft, causing your car to fail entirely.

How to Check Your Engine’s Compression

When you experience sketchy car performance or your vehicle misfires at the turn of your key, the first step is to conduct a compression test. Because many elements can trigger low or no compression in an engine, the test can help you find the internal problems that are causing the loss of compression.

Before using a compression gauge, make sure you remove all the spark plugs and deactivate the ignition coils or ground the high tension lead. If your vehicle’s engine has a distributorless ignition, you must disable the ignition coils to keep them from firing. Once you’re set up and ready, hold open the throttle and crank the engine for several seconds while the compression gauge is in a spark plug socket. Record the maximum compression reading, and repeat the test for each cylinder.

If it turns out your engine has low compression, you can conduct a cylinder leak down test, which will help you see what’s happening internally. You can then pinpoint where the specific leaks are occurring. A leak down test uses pressure gauges along with a regulating device. Together, they provide information that allows you to quantify the percentage of leakage.

What Causes Loss of Compression in an Engine?

We wish we could tell you there was a single reason for compression problems, but when it comes to the causes of low or no engine compression, there are eight different potential components. Common snags such as bad valves, piston complications, leaks in the cylinder head and faulty timing belts are just the beginning.

When you know what causes leaks, it can help you understand the source of compression loss, making it easier to fix. We’ll cover each possibility and discuss what you can do to repair the engine.

1. Holes in the Piston

Located in the cylinder of an engine, pistons receive an excessive amount of wear because they’re next to the combustion. Each time you fire the engine, the piston gets blasted with the explosion. When combustion occurs, it expands the compressed gases and moves the piston, which, in turn, operates the crankshaft.

Because the cylinder experiences extreme temperatures from the air and fuel mixture, overheating can occur. It forms hotspots on the piston and can cause holes or cracks in the piece. When holes and gaps form between the piston and the wall, they allow the gases to leak, resulting in low engine compression.

Instead of the gases building up in the chamber, they leak and create a loss of energy. Components that can trigger hotspots include gas with a low octane, bad spark plugs and malfunctioning fuel injectors.

You can check for battered pistons by pouring oil into the spark plug socket and testing for compression. If it’s higher than average, you have a piston issue. You can also take out each piston and visually inspect them to see which ones are suffering. Holes in a piston affect an engine by causing low or no compression in a single cylinder.

2. Leaking Valves

Intake and exhaust valves often face impairments from an overheated cylinder. The extreme temperatures can warp and ruin the valves, causing them not to seat or close properly. Once the seal breaks between the valves and the cylinder, the gases can leak. The result is compression loss.

In a vehicle, the intake and exhaust valves are at the top of the engine’s cylinder. The intake is where fuel and air pass through into the cylinder. When the elements combust, the exhaust valve gets rid of the gases. The exhaust valve fails more often because it has the most exposure to the heated gases that can reach temperatures between 1,200 and 1,350 degrees Fahrenheit.

The heat can either distort or break the valves, causing excessive leaks and compression loss. The cylinder’s valves can also gain carbon buildup, which often occurs on the exhaust as well. Carbon buildup happens here the most because it’s where a constant flow of burnt gases happens. Excessive amounts of carbon can destroy the seat, diminishing the seal on the valve.

Place a compression tester in the spark plug socket, and crank the engine. The test will show if there are problems with the valves. You should also be aware of leaks from the exhaust pipe or the air inlet manifold. Leaking valves can be a reason for low ignition in a single cylinder.

Impaired valves can also be due to a faulty computer system that tells the intake and exhaust to open and shut at the incorrect times. Make sure to check the computer or electrical system if the valves still don’t operate well.

3. Blown Head Gaskets

Blown head gaskets or cylinder head leaks are the third culprit to low engine compression. You can find the cylinder head at the top of the engine block, and the head gasket is between the bottom and top half of the car’s engine. The gasket separates the oil from the fuel and air mixture while allowing the gases to move into the cylinder to cause combustion. After the gases burn, they exit through the exhaust valve.

The cylinder head has a gasket between itself and the engine block. If the gasket deteriorates or breaks, a hole or gap can form airspace between the head and the cylinder. The engine can also have a gasket that is misaligned, worn, cracked or warped. This is known as head gasket failure. It can prompt the gases to escape, causing compression loss. Head gasket failure is often attributed to overheating.

An outcome of lost compression includes diminished engine performance. You can use a pressure tester to determine where the damaged gasket is by measuring the cylinder’s compression level. If you record different readings, check the gaskets to find the problem. If two cylinders are damaged next to each other, a blown gasket is often the reason. Cylinder leaks are the reason for low compression in a single cylinder.

4. Glazed or Splintered Cylinder Walls

A cracked wall in the engine’s cylinder can elicit poor compression. You can investigate the problem by working with an open radiator cap. Crank the motor and see if air bubbles come out. If so, the bubbles indicate leaked combustion gases that found their way through the splintered cylinder and into the cooling system.

5. Weakened Timing Belt or Cracked Chain

A timing belt is a component that bridges the crankshaft and camshaft. It controls which pistons are up and down to move your vehicle. When one piston moves downward from the ignition, the timing belt turns and moves other pistons up.

The camshaft can’t function and turn when the timing belt fails. Therefore, the intake valve cannot close, and the exhaust will seal inside the cylinder. It’s all a chain reaction throughout the engine. On average, a timing belt can last between 60,000 and 100,000 miles before it needs replacing. The trapped gases inside the combustion chamber can cause low or no compression in all the cylinders.

6. Worn Piston Rings

Three rings support and connect the piston to the shaft. The top ring seals the piston to the cylinder’s walls, and the second ring catches anything missed by the first. The final ring helps control the amount of excess engine oil by wiping it away.

The shaft moves several pistons up while lowering the others at an alternating pace. Any worn-out piston rings in an engine can overheat and give way to gases leaking into the crankcase. When the pistons don’t operate properly, they may not move as high as necessary or raise at all.

You can test the issue by pouring viscous oil into the spark plug socket, which will allow the liquid to reach the combustion cylinder. If the compression increases, you can tell there is a piston or piston ring problem. While the pistons may encounter damage from overheating and fail to seal in the gas, they are still intact. Worn rings can cause low compression in one or all cylinders.

7. Damaged Valve Springs, Seats and Retainers

A lot of lost compression is due to faulty valves. In this case, the engine can possess damaged valve springs, seats or retainers. Valve springs help the intake and exhaust valves to close after the camshaft opens each one. While the springs are constructed from high-tension steel, they can also be quite brittle. If a spring breaks, the valve cannot close all the way, and the ignited gases can leak.

A valve seat is a metal ring pushed against the cylinder head. Mostly made from aluminum, they can expand from overheating and loosen. Once loose enough, the seat can fall off the head and allow air to escape into the port. You can either repair or replace a dropped valve seat.

Finally, a valve retainer is a tiny piece located in the valve spring that can dislodge. Retainers keep the valve connected to the spring. But if it dislocates and drops into the cylinder, it can touch the piston and interfere with the ignition process.

All three elements of the valve can affect an engine by causing no compression in one cylinder.

8. Worn Out Camshaft

Camshaft lobes attach to valves, triggering them to open and shut. Like everything in your car, they can deteriorate over time and prevent the valves from opening. It can set off a chain reaction — when the valves can’t open, the ignited gases remain in the chamber. Worn camshafts can be a reason for low compression in a single cylinder or can result in no compression in all the cylinders.

You can check the issue by taking off the valve covers and turning the engine over. Watch how the valves react and replace the camshaft as necessary.

Understanding the eight potential reasons for an engine’s compression loss is vital in keeping your car in operation and avoiding the repair shop. The more you know, the more likely you can fix the issue yourself and get on with the more important things in life — like enjoying that Sunday afternoon drive.

In most cases, your engine will encounter low compression in one cylinder with a misfire when you start your car. The problem becomes more serious when there are more than one that have issues, or if the engine has no compression and won’t start.

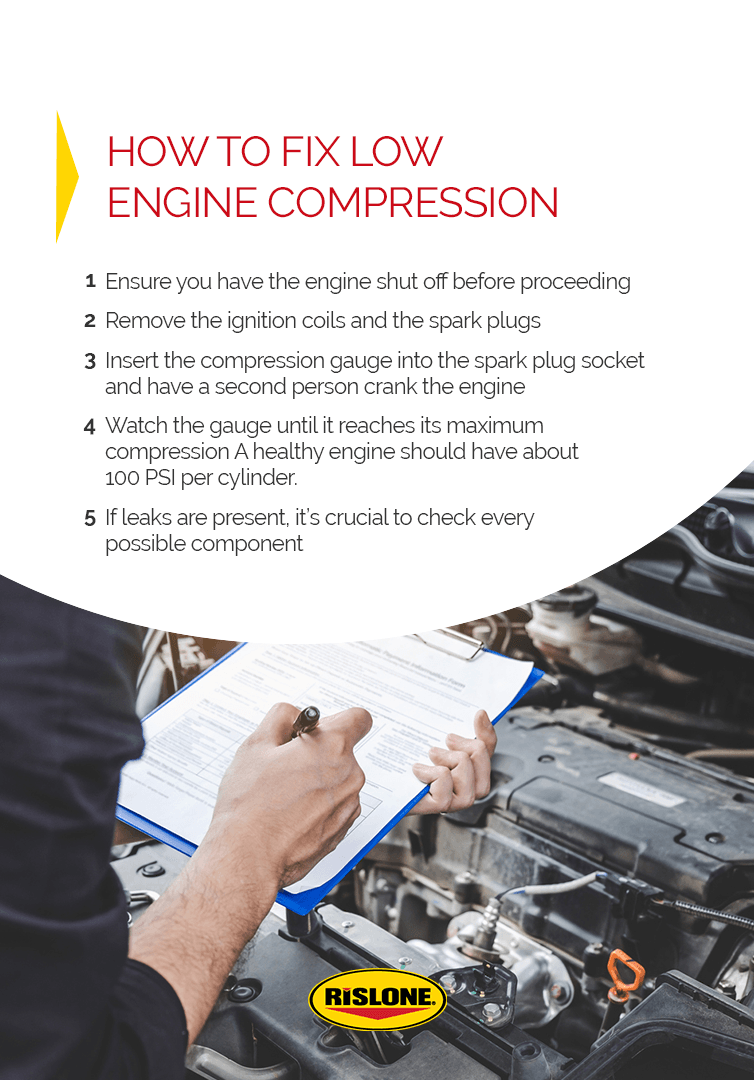

How to Fix Low Engine Compression

If you suspect your vehicle is suffering from low or no engine compression, you’ll want to make sure your hypothesis is legitimate. The first step is to determine whether there is an actual loss of compression in one or several cylinders by conducting a compression gauge test.

Ensure you have the engine shut off before proceeding, then remove the ignition coils and the spark plugs. Insert and tighten the compression gauge into the spark plug socket and have a second person crank the engine. Watch the gauge until it reaches its maximum compression. A healthy engine should have about 100 PSI per cylinder. If leaks are present, it’s crucial to check every possible component.

Examine everything from the piston rings, gaskets and camshafts to cylinders, valves and pistons. Look for cracks, worn areas, holes, damages or slits. Once you discover one or more broken cylinders, start repairing or replacing the parts.

Rislone Treatment Solutions

Some pieces need physical repairs, while less severe leaks can be treated with products. For example, Rislone provides you with our Compression Repair with Seal Ring (4447). It’s an engine compression restoration treatment that can unstick piston rings and fill a cylinder’s scratches and wall gaps. The solution can also decrease wear and friction as well as renew worn engines, repair blow-by, rebuild compression and restore power.

The makeup of the product doesn’t involve harmful leads that have the potential to damage your engine or other risky metals that can contaminate various components. It has a blend of petroleum additives that are ideal for high-mileage engines experiencing decreased or no compression.

Rislone engineers use a special additive to repair degraded cylinder walls to restore compression and boost engine performance. Our compression repair treatment works in two ways. Chemical polymers fill in the grooves, dents and scratches within a cylinder. Any abrasions can be caused by age, wear and high mileage. The solution also helps free up sticky rings located in the piston’s grooves, helping them to seal better and fix compression leaks.

Many times, faulty compression requires repairs and replacements, but in other cases, you can find a solution like ours that supports all petroleum-based oils and works with gas and diesel vehicles.

When you rely on our expertise and exceptional products, you can mend low compression mishaps and enhance your car, truck or SUV’s operation. We can even help you advance the longevity of your vehicle. As it drives in the elements and coasts through thousands of miles, your car can withstand harsh conditions. But if you don’t supply the engine with proper care, the system can degrade faster than usual.

Treatments for Low Engine Compression

Rislone has been at the forefront of performance chemicals for more than 95 years, supporting people who want to repair and improve the peak operating levels of their car. Our products like engine treatments, fuel and diesel treatments, compression repair formulas, zinc oil additives and transmission repair fluids help to maintain and boost vehicle performance.

Learn more about our compression treatment product and how it can support your engine, or search for a location near you offering our solution. If you need additional support on how to repair low engine compression, you can rely on our team of experts for personal and trustworthy assistance.